Perfection to the smallest grain of sand.

Not all sand is created equal! On the contrary: It’s a science in itself.

But luckily, every scientific discipline has its experts, and we exploit their expertise for our riding arenas.

As one of the world's leading suppliers of riding surfaces, we have been discussing the properties of a wide range of different sands with these experts for decades. Research is also ongoing into a wide range of aggregates and additives to optimise the footing sand.

We have our own sand lab, and have been researching the optimum footing mix for horse and rider for many years. The result: OTTO-ArenaTex.

For major competitions or the small local stables or riding school: The OTTO-ArenaTex footing is suitable for any requirement. Our motto: the same high quality for any application. Because your horse is important to us!

The features

The sand content in OTTO-ArenaTex-footing consists of pure quartz sand. This is an extremely hard grain that does not crack even under high and prolonged stress and therefore lasts a very long time. In addition, the textile-fibre mixture, OTTO GeoTextil, is made of extremely robust material.

The OTTO-ArenaTex formula combined with an appropriate level of daily maintenance thus becomes a riding surface that will last you an incredibly long time.

“On my yard in Nottingham, lots and lots of riding is done on the surfaces every day. We train for the most high-ranking shows worldwide, so the surfaces are need to be able to handle that.

Still, my OTTO-ArenaTex Footing has lasted for over 10 years (Interview in 2016). Especially after the guys from OTTO Sport laser-graded the arenas again for the first time since installation recently, the footing feels like on the first day.”

Billy Twomey

British show jumper

Puddles in the riding arena are not only a nuisance - many horses even refuse to perform the course because of them. In addition, muddy paddocks lead to unpleasant hoof diseases in the long term.

The solution: OTTO-ArenaTex footing allows all excess water to drain away quickly as it does not contain any substances that would obstruct water drainage (e.g. clay). When installed with the appropriate sub-base layer and a water-permeable footing, this means that not a single drop will ever remain on the top of the riding surface.

Muddy paddocks and a hazardous riding surface are now a thing of the past.

“We used to cover our outdoor arena up with a PVC liner before every rainstorm, and even then we couldn’t ride right after the storm was over.

But ever since we installed OTTO Sport, the water drains immediately. We can even ride during the famous ‘El-Niño’ storms when we have rainfalls with up to 180 mm. This has been really fantastic.”

Shannon & Steffen Peters

Olympic dressage ridersSee the full interview here!

As sand is a water-bound material, the footing must always be kept in an earth-moist condition so that the horses have a secure grip and no dust can be stirred up. A riding surface that requires frequent watering can be very time-consuming, energy-intensive and costly.

It is precisely for this reason that OTTO-ArenaTex footing includes a textile aggregate.

Up to 6 litres/m2 of water can be stored in the textile-fibre element of the OTTO-ArenaTex footing. This can rise to a water retention level of up to 10 litres/m2 when combined with the water storage system of the OTTO-PerforatedMat™!

In the case of outdoor arenas, rainwater can therefore replace the majority of the manual watering, which can save considerable costs in terms of tap water.

The textile-fibre content of OTTO-ArenaTex footing also increases the elasticity of the surface (see point 5!).

Safety and health of horse and rider are decisive factors in the selection of the right footing, both at high-profile competitions such as the Olympic Games and at the small local stables or riding school.

That’s why countless riders worldwide have trusted in the quality of the tried and tested OTTO-ArenaTex footing for decades.

A sand mixture that is too round-grained does not provide adequate support for the horse's hooves. At the same time, too sharp a mixture can have a damaging effect on the hooves.

The sand mixture in the OTTO-ArenaTex footing contains the perfect composition of grain shapes to achieve this fine balance.

After all, the sand experts at OTTO Sport have been researching this science every day for decades.

In addition to the ideal sand mixture, the OTTO-ArenaTex footing is also equipped with special fibres that behave like a root system in the footing and prevent excessive sand displacement.

The result: The sand-fibre mixture provides a secure grip for the horse's hooves even in tight turns.

A high degree of elasticity is very important in all equestrian disciplines. An elastic surface returns the energy of the hoof to the horse, which has an immediate effect on performance and safety and a long-term positive effect on the health of the horse.

OTTO-ARENATEX, particularly combined with the legendary OTTO-PerforatedMats™, provides the perfect degree of elasticity for the riding surface.

The high degree of elasticity in the OTTO-ArenaTex footing is owing to the textile content. In addition to its water storage properties (see point 3), the textile-fibre is also extremely springy.

When combined with the OTTO-PerforatedMat™, this results in an enormous increase in performance.

Similar to any quality product, the OTTO-ArenaTex footing requires the appropriate care and maintenance. Fortunately, the care and maintenance is very simple.

- Daily, thorough removal of contaminants such as horse droppings, leaves, etc., prolongs the service life of the footing.

- The footing can be easily kept in tip-top condition using the correct professional maintenance equipment. (Click here for the OTTO-ArenaLevellers)

- After cleaning, the footing should be adequately watered.

FAQ

OTTO-ArenaTex is water-permeable. In combination with a correctly installed subbase, this means that any excessive water can drain through the footing layer and all of the lower layers. By means of the arena’s incline, the water can then flow to the side and out of the arena. This way, any puddles or mud will be avoided.

At the same time, a sufficient amount of water is stored thanks to the additives in the sand, so that a certain amount of moisture is retained in the footing, provided that adequate maintenance is carried out. OTTO-ArenaTex can store up to 4 liters of water more per sqm than other types of footing.

Ein weiteres Plus ist die Konsistenz des Reitbodens – ein wasserdurchlässiger Boden behält seine Elastizität, im Gegensatz zu Böden mit Oberflächenentwässerung, die zu diesem Zweck über eine entsprechend feste bis harte Oberfläche verfügen müssen.

Silica sand is almost abrasion-free and hardly contains any fine particles. Also, nearly pure silica sand does not contain any clay. These features prevent the footing from clogging the drainage system and, hence, guarantee trouble-free drainage.

Moreover, silica sand is a very hard grain and almost abrasion-free, which makes it very durable and long-lived.

We recommend using sand with silica content of min. 95%. Our own OTTO Sport blends have silica content of up to 99.9%.

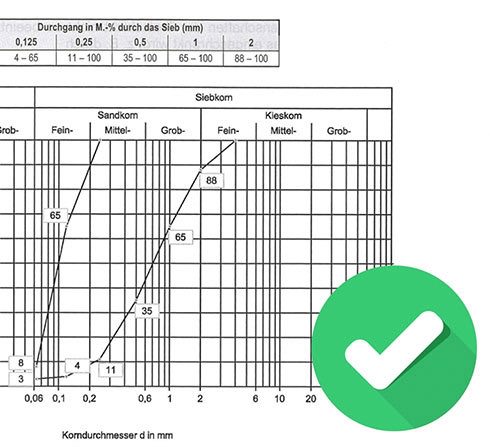

OTTO-ArenaTex Footing is a blend of several high-quality silica sand types which are mixed according to the individual requirements. In our own sand laboratory, the exact grading curve can be determined which provides excellent information about the sand quality. The fineness of the grain as well as the correct combination of grain sizes within the sand mixture are of considerable importance in this regard.

Silica sand tends to have the reputation of grinding down the hooves. But not the OTTO-ArenaTex Footing! The horses’ health is very important to OTTO Sport. Therefore, they pay close attention to a balanced mixing ratio of round and edgy sand grains.

Silica sand tends to have the reputation of grinding down the hooves. But not the OTTO-ArenaTex Footing! The horses’ health is very important to OTTO Sport. Therefore, they pay close attention to a balanced mixing ratio of round and edgy sand grains.

The sand part in the OTTO-ArenaTex Footing has a grading curve of < 0.5mm. The grain fineness is a decisive factor for high-quality equestrian sand. However, the ideal composition of several grain sizes is just as important for the perfect consistency of the footing. The sand must be able to provide low caving-in under the hooves, firmness and grip, especially in showjumping.

Due to its natural hardness, silica sand is nearly abrasion-free and, therefore, produces almost no fine particles.

The OTTO-ArenaTex (sand/textile/fiber blend) has several advantages. For one, it provides increased elasticity to the otherwise very hard sand layer. Also, it binds the sand to some extend. The most important feature, however, is that it can store water. The OTTO-ArenaTex Footing can store up to 4 liters more per sqm than regular types of footing.

OTTO Sport recommends adding the OTTO-GeoTextile additive, a textile/fiber blend, which can be used for every regular equestrian discipline.

Moreover, it is possible to use only natural material, i. e. sawdust. The OTTO-ArenaSpan blend is produced exclusively upon order. The lifespan of sawdust, however, is considerably shorter than the OTTO-GeoTextile’s. Due to the natural wood material, abrasion is a lot higher and, therefore, dust is produced. Also, this footing has to be filled up from time to time.

Of course, given the large number of additive providers on the market, materials and quality vary. The important thing is that the additive does not dispense any additional fine particles and is dust-free. Moreover, the lifespan of a textile/fiber blend is considerably higher than that of sawdust.

Using footing without additives is possible, but OTTO Sport do not recommend it to a limited extend, except in paddocks. For showjumping under tournament conditions, a sand footing without additives is not suitable, as the required quality for this purpose cannot be achieved in this case.

If footing is used without additives, we point out that a considerably higher maintenance effort is needed in this case. In order to achieve sufficient stability in the sand, a larger amount of irrigation is required.

The textile in the OTTO-ArenaTex Footing can store up to 4 liters of water per sqm.

Sand is a natural product. Therefore, colors may vary. However, this does not affect quality in any way.

Yellowish silica sand is more rare than white silica. Choosing the right color of the sand is mainly a matter of preference. However, in areas with high sun exposure and longer hours with sun, footing with a higher content of yellow sand is recommended as it does not reflect the light so much.

In classic equestrian arena construction with the OTTO-PerforatedMat, we recommend installing the footing with a layer thickness of only 8 – 10 cm, measured from the top edge of the knobs. If, for whatever reason, you do not wish to install the OTTO-PerforatedMat, the footing layer needs to be raised to a thickness of approx. 12 – 15 cm.

When constructing an OTTO-Ebb&Flow arena, a layer thickness of approx. 13 cm has to be calculated to ensure the capillary effect from the subbase up into the footing. After installation, the layer thickness also amounts to approx. 10 cm measured from the top edge of the knobs.

Regular irrigation and daily removal of droppings and other dirt (e. g. leafs, wood etc.) will extend the lifespan of the footing considerably. Otherwise, the sand may clog up after some time and limit the drainage ability of the surface.

Moreover, it is recommended to level the arena regularly by means of arena leveling devices. This levels uneven spots, fills holes and levels the hoof track around the arena. When the surface has packed down too much, the harrows should be applied to the surface with a depth of 1–2 cm. Please refer to our “Maintenance guide for your original OTTO Sport Equestrian Arena”.

OTTO recommends using an arena leveler from their own range, whether it is the OTTO VARIO or OTTO DELUXE – each with individual features which will fit your needs perfectly.

For more details about the individual models, please contact our sales team

On a chemical basis, horse excrements have no effect on the footing. Merely the manure may cause the sand to clog up if they are not removed on a daily basis, which may limit the footing’s drainage ability.

Any sand footing, no matter what type, needs to be irrigated, as sand is a water-bound material. This way, ideal, long-term consistency of the footing is ensured. Thanks to the additives in the OTTO-ArenaTex Footing, a considerable amount of water is already stored within the footing and passed on to the sand (4 liters per sqm). Still, irrigation is mandatory.

Due to the longevity of silica sand and the fact that the OTTO-GeoTextile additive does not decompose, the OTTO-ArenaTex Footing’s lifespan is nearly limitless, but subject to conscientious maintenance.

Regarding the exact mixture of the OTTO-ArenaTex Footing, there is no difference between indoor and outdoor arenas. However, when it comes to the entire build-up of layers for the arena, an incline of approx. 1% has to be created outdoors to ensure water drainage. This is not necessary indoors.

In classic equestrian arena construction with the OTTO-PerforatedMat, we recommend installing the footing with a layer thickness of only 8 – 10 cm, measured from the top edge of the knobs. If, for whatever reason, you do not wish to install the OTTO-PerforatedMat, the footing layer needs to be raised to a thickness of approx. 12 – 15 cm.

When constructing an OTTO-Ebb&Flow arena, a layer thickness of approx. 13 cm has to be calculated to ensure the capillary effect from the subbase up into the footing. After installation, the layer thickness also amounts to approx. 10 cm measured from the top edge of the knobs.

The gait of Icelandic horses is tölt. For this, a special blend of footing is required. Please contact us if this is the case for you.

If you have a quartz sand works in your area or specific contacts you’d like to use, please send us a sample (approx. 500 g) of the sand you want to use. We will examine the sample in our laboratory for its properties and immediately notify you whether its composition is suitable for the requirements of your riding surface.

A sieve analysis includes an examination of the grain fineness (or ‘dispersity’) and the gradation of the individual grain fineness levels relative to each other. This analysis is to determine if the sand meets the quality requirements of a riding surface.

Grundsätzlich empfiehlt OTTO den Einbau einer Trennlage aus OTTO-Lochmatten.

Reitplätze, die nicht über OTTO-Lochmatten als Trennlage verfügen, bedürfen einer besonders gewissenhaften Pflege. Durch ausreichendes Bewässern ist sicher zu stellen, dass der Boden zu keiner Zeit austrocknet. Damit wird die notwendige Festigkeit der Tretschicht gewährleistet, die einem Vermischen mit dem Unterbau entgegenwirkt.

A firm, load-bearing substructure is a prerequisite for the construction of a riding surface. This is not advisable if the substructure is topsoil, a field or mud. The appropriate measures must be taken based on the property of the substructure.

Please contact us if you would like to organise a viewing appointment with one of our riding surface experts.

The OTTO-ArenaTex mixture is a multifunctional footing that can be individually adapted for any discipline.

No aggregates are required for paddocks. Enquire about OTTO-ArenaPur, our paddock sand.

The OTTO ArenaTex footing is delivered loose or in large sacks, generally by a freight forwarder. The packaging is individually tailored to the respective order or place of delivery within Germany or to other countries.

If the footing is delivered by semi-trailer truck, the site must be accessible for a 40-ton truck. The construction site or approach road must be easily accessible and paved.

OTTO-ArenaTex can be disposed of normally at your local landfill site. You can also separate the sand from the textile-fibre mix using a (humus) screening plant and it can then be reused e.g. for agricultural purposes.

Alternatively, many construction companies are willing to take the sand mixture to line cable trenches for example.

The quartz sand used by OTTO Sport is clean sand which does not leach out any other substances, and does not therefore pollute the groundwater.

The functionality of the OTTO ArenaTex footing has a 2-year guarantee.

Yes. All the sand samples are tested by OTTO in the laboratory using the same analytical methods. We only recommend sand that achieves the corresponding high standards, and we can therefore guarantee a consistent and high quality worldwide.